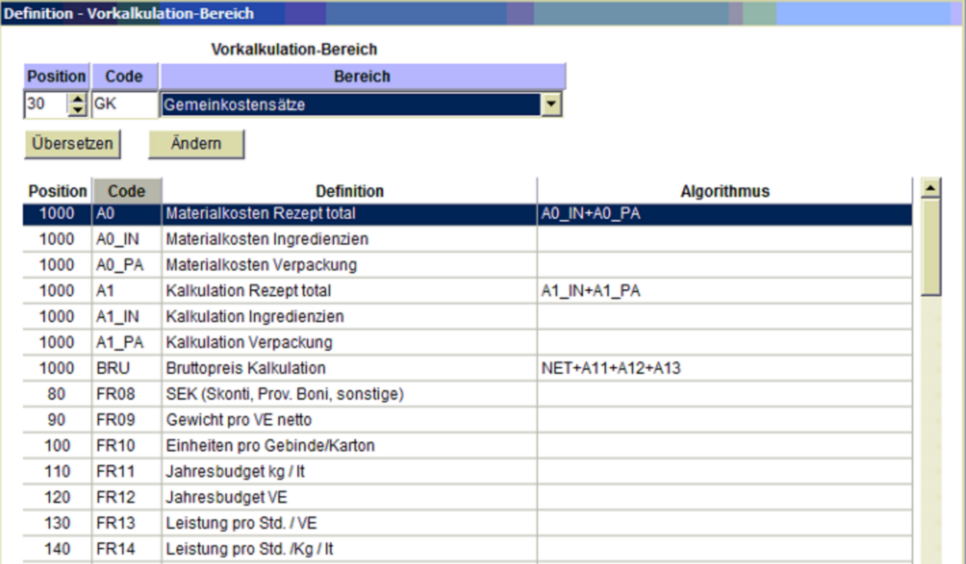

Each calculation layout must always contain the following fields:

•Calculation Ingredients (A0_IN)

oThis parameter contains the sum of all raw material costs.

oThis parameter must always be at the beginning of each calculation, regardless of whether it is needed or not. If it is not used, the parameter can be hidden using the "Sales" checkbox.

•Calculation Recipes (A0)

oThe parameter "Calculation Recipes must always be included in the cost accounting, regardless of whether it is needed or not.

oWhen not in use, it can be hidden, but must still be included in the cost accounting.

•Own cost rates

oAny number of own cost rates with or without formula can be created and inserted into the cost accounting.

oPlease note that the cost accounting always calculates from top to bottom. Fixed positions can be highlighted and hidden, but must always be inserted above the usage.

•Gross costs - Calculation (BRU) - Last position

oThis cost rate must always be included in the calculation, even if it is not needed. Please note that if a formula is used, "Algo" is also selected.

|

Note: Alternatively, A1_IN and A1 can also be used instead of A0_IN and A0. These are the same blocks as A0_IN and A0. The only difference is that these cost records do not receive an update from the program after loading. No update related to selected price sets and or updates related to changes in the price of the Master data. These fields can be manipulated compared to A0_IN and A0. |

All available fixed fields with references from other PDM modules in the appendix.

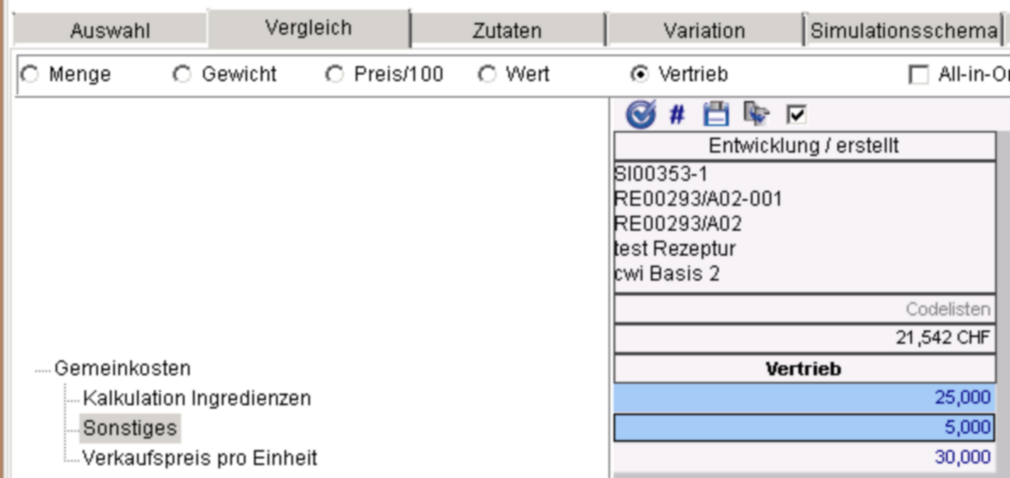

Example:

In the example above, the fields "Total recipe calculation" and "Gross price calculation" are hidden.

In the simulation only the three visible fields "Calculation Ingredients", "Other" and "Sales Price" are visible. The field "Calculation Ingredients" has been overwritten with SFr. 25.00, which makes SFr. 30.00 in total with the other costs.

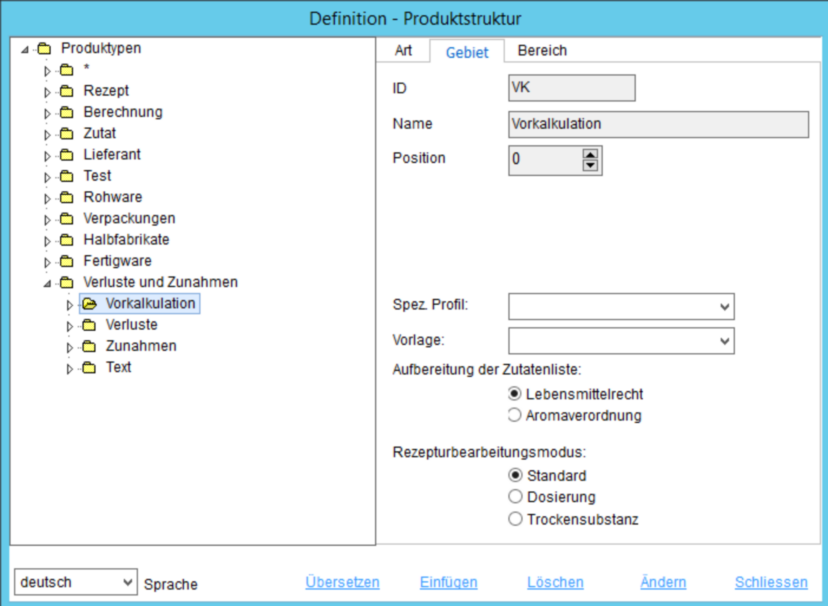

Administration: All master data must be stored in a defined product structure under losses. This is defined via the program parameter VORKALK_PRODGEB.

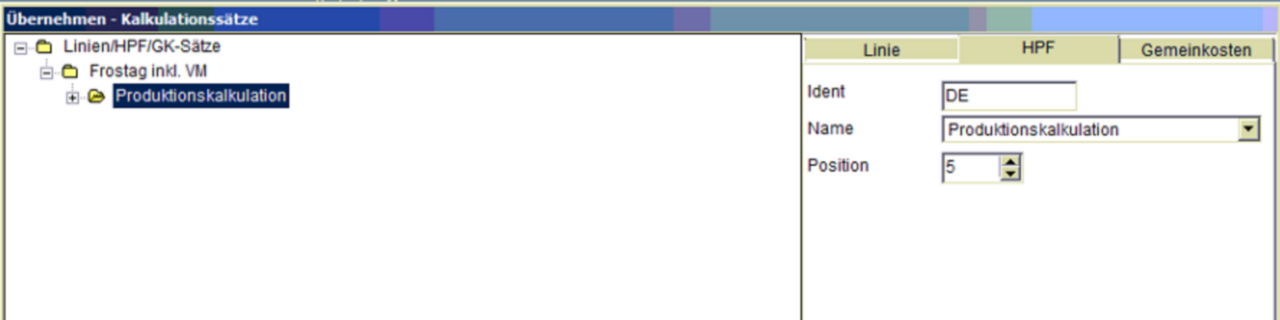

In the example below the Ident "VK" is stored in the above mentioned parameter.

Illustration 1: Defined storage of calculation records under the ID "VK"

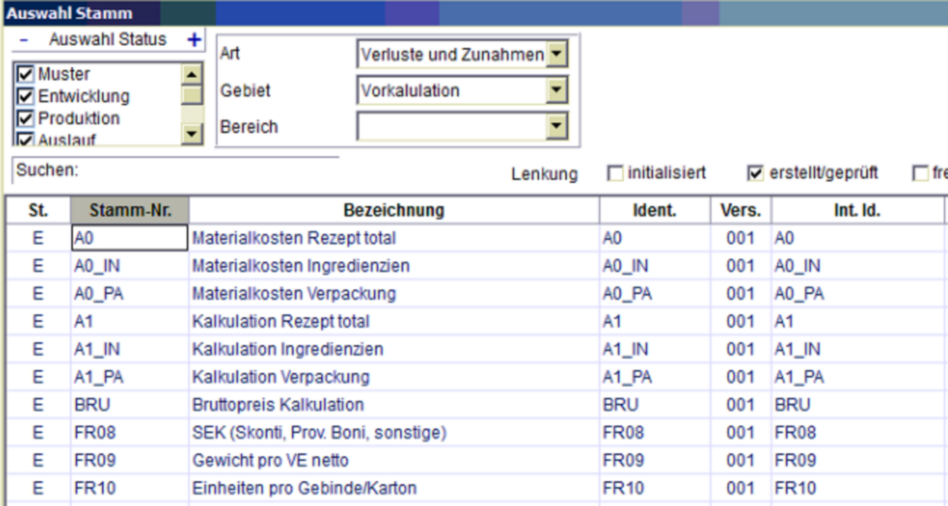

All necessary criteria (cost rates) must be created in the master data under the product structure: Losses/Increases → Preliminary Costing.

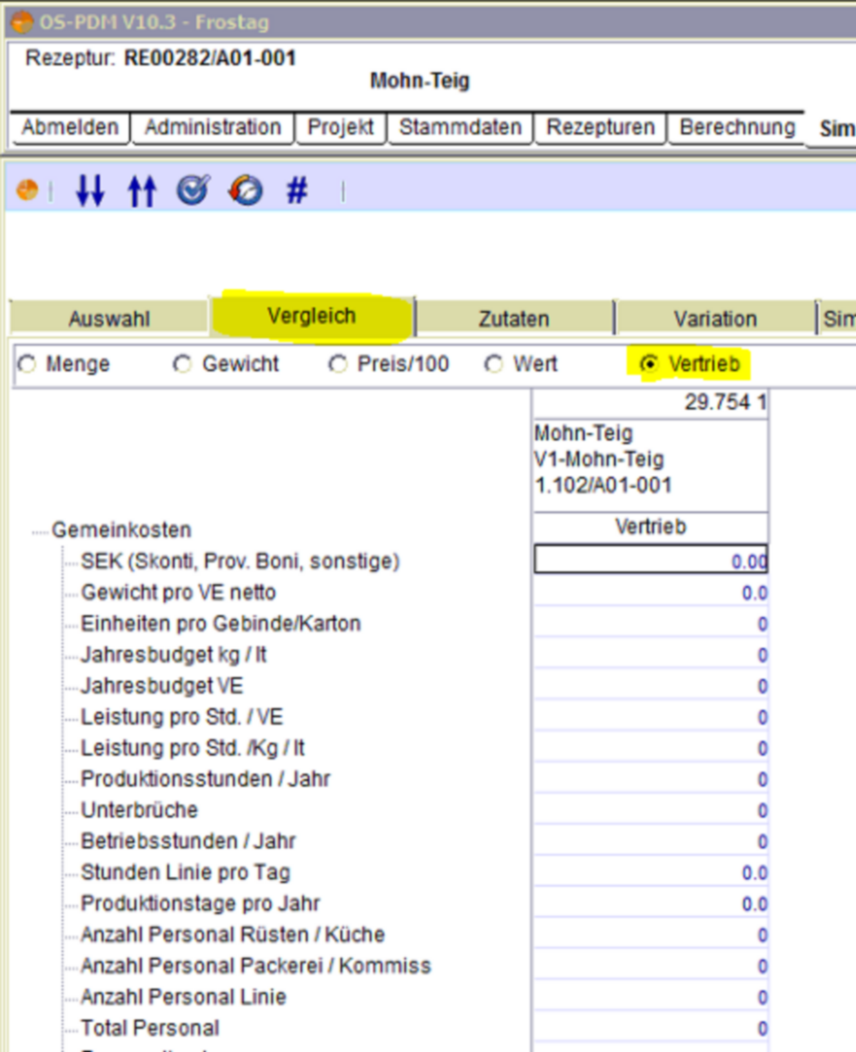

To make the simulation calculate, some standard fields must be created and used. But these can be hidden for the overhead calculation.

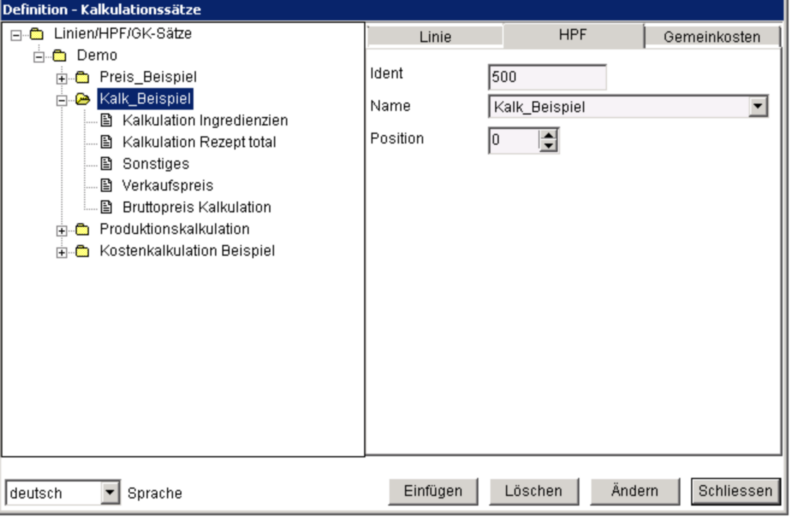

All cost rates required for overhead cost accounting plus the fields required for functionality must be entered here a second time in the "Overhead rates" area. It is important to note that the code is the same as the Ident of the above mentioned Master data.

All fields that were created under the button "Preliminary costing records" are now available in the costing records.

It is important to note that:

•The calculation needs some fields as standard first and last of every cost calculation, regardless of whether they are used or not.

•The identity of the field is used for the algorithm.

•The calculation is calculated from top to bottom. That means fixed values and intermediate results must be above the usage.

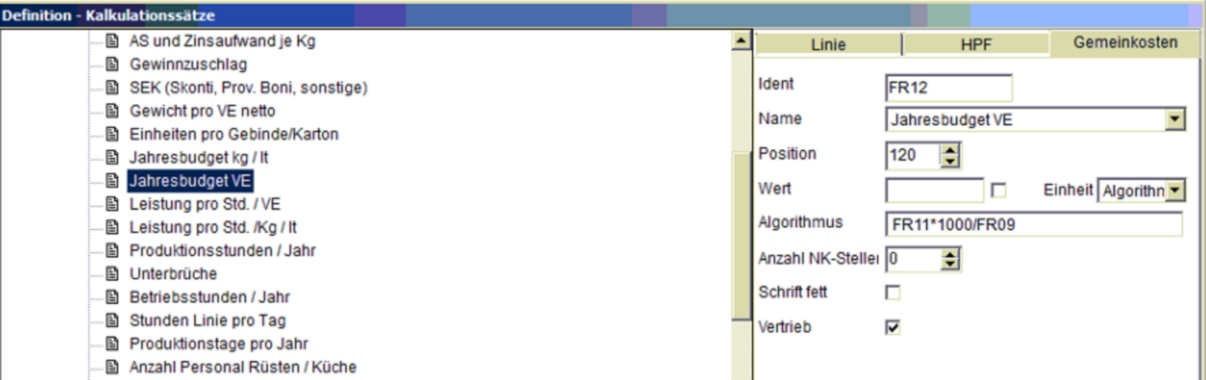

Description:

Ident: |

Field identifier |

Name: |

Field name |

Position: |

Position in cost accounting |

Value: |

Default value |

Checkbox: |

Checkbox display instead of value. Effect: Value is used y/n |

Unit: |

empty, currency, %, algorithm (algorithm cannot be overwritten) |

Algorithm: |

Calculates from left to right (dot before stroke rule is not considered). References to previously made fixed values must be calculated with x1 [times]. |

Number NK-St.: |

Number of decimal places |

Font bold: |

Display of the criterion "bold" y/n |

Sales: |

We under the radio button "Sales shown" y/n |

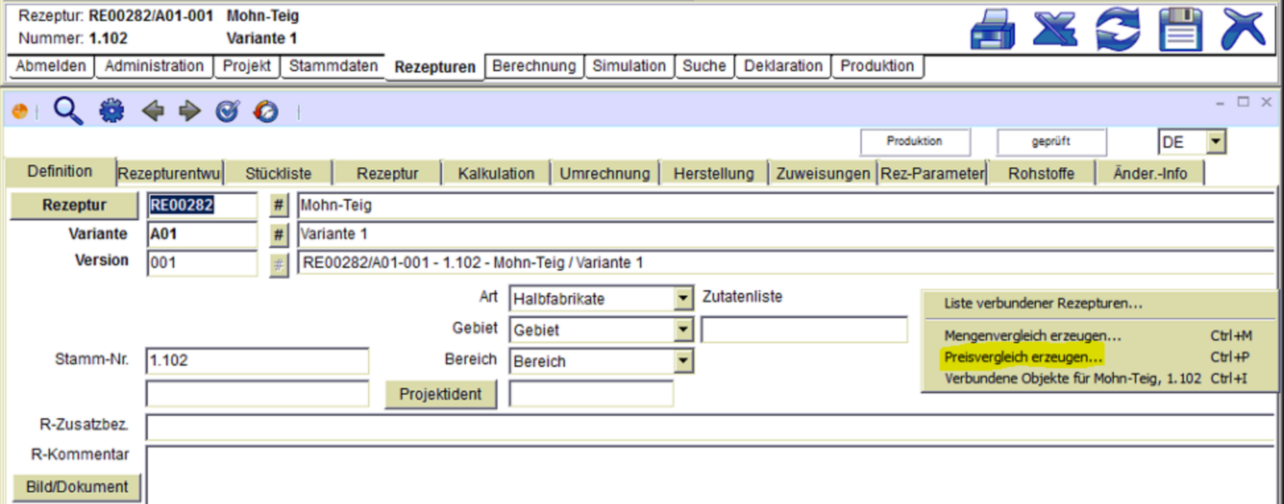

Under the "Recipe" tab, the recipe required for cost accounting is called up.

Via the right mouse button the function "Create price comparison...". is called.

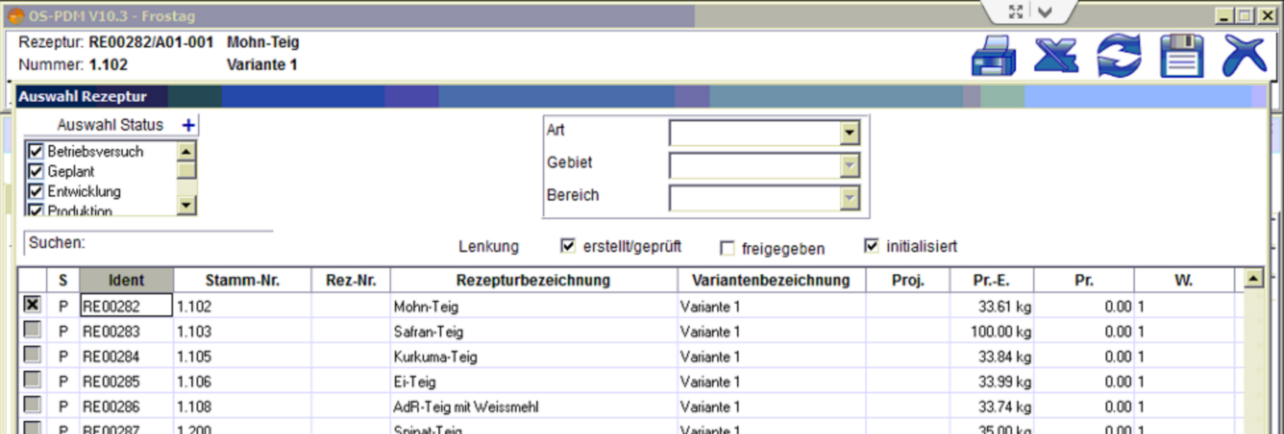

The next dialog shows the selected recipe. Further recipes can be selected by marking the checkbox on the left. With the button "Accept" the selected or chosen recipe is accepted.

In the next dialog the cost scheme is selected. There is currently only one scheme available below. Click on "Apply" to start the costing calculation.

The cost-plus calculation is ready. Filling out the fields starts from top to bottom.

Under the radio button "Sales" only the marked and selected fields are shown.

Under the radio button "Quantity" all raw material unit costs and all criteria necessary for cost calculation are shown. This function can be hidden via the authorization.

The export can be done by clicking the "Excel" button in the upper right corner.

Red |

required fields, which must be included in the calculation |

Green |

fields from the work plan |

Blue |

Fixed costs from material and recipe |

Ident |

Name |

Formula |

A0 |

Material costs Recipe Total |

A0_IN + A0_PA |

A0_IN |

Material Costs Ingredients |

|

A0_PA |

Material costs packaging |

|

A1 |

Calculation Recipe Total |

A1_IN + A1_PA |

A1_IN |

Calculation of ingredients |

|

A1_PA |

Packaging calculation |

|

A2_IN |

Calculation loss of ingredients |

A1_IN * A2_IN / 100 |

A2_PA |

Calculation loss of packaging |

A1_PA * A2_PA / 100 |

ANALY |

Analysis costs |

Costs from the Test Plan module |

COMMUNICATIONS |

Quantity supplied |

Ident of the cost rate [quantity offered] |

BASICS |

Recipe base quantity |

|

BR2 |

Gross price (target price) |

|

BRU |

Gross price (calculation) |

|

COUNT |

Number of components |

|

DEB |

Contribution margin |

A1 * DEB / 100 |

DOSAG |

Cost rate Dosage Formulation |

|

FKFIX |

Production costs Fixed costs Basis |

Full costs - marginal costs |

FKGK |

Production costs Marginal costs Basis |

marginal costs |

FKGK1 |

Production costs Marginal costs V 1 |

|

FKGK2 |

Production costs Marginal costs V 2 |

|

FKVK1 |

Production costs Full costs V 1 |

|

FKVK2 |

Production costs Full costs V 2 |

|

FREE |

Shipping costs |

Idents of the cost rates for freight costs - specification with comma separation |

GHK |

marginal production costs |

Ident of the cost rate |

IDB |

Contribution margin calculated |

Ident of the cost rate |

L2_L5 |

Overhead costs for ingredients |

A0_PA * L2_L5 / 100 |

L6_L9 |

Packing overheads |

A1 * L6_L9 / 100 |

MEK |

Material input costs |

Ident of the cost rate |

MGKF |

Fixed material overheads |

|

MGKV |

Material overheads variable |

|

OFFER |

Quantity supplied |

Ident of the cost rate for the supply quantity |

RGKF |

Fixed recipe overheads |

|

RGKV |

Recipe overheads variable |

|

TE |

Labor costs production |

Ident of the cost rate |

TEB1 |

Variable investment costs |

Ident of the cost rate |

TEB2 |

Fixed investment costs |

Ident of the cost rate |

TR |

Wage cost setup |

Ident of the cost rate |

TRB |

Investment costs for setup |

Ident of the cost rate |

VHK |

Production costs Full production costs |

Ident of the cost rate |

SALES_QUANTITY_AT_SIMUIf |

set, the data of the recipe sales column is used for the new price simulation |

SIMU_ALLINONE_EXPCOL |

1=export column, 0=skip column. Order: (quantity;weight;price;value) |

SIMU_AUTO_COMPARISON |

Automatically reflect changes in comparison preferences in the comparison view. |

SIMU_AUTO_IP_COSTS |

Automatically track test plan costs to simulation. |

SIMU_AUTO_MAT_PRICES |

Automatically adjust material prices to simulation. |

SIMU_COMPARISON_HEADER |

Heading of simulation comparisons. 0: Simulation ident, 1: Recipe id/variant / version, 2: SAP number, 3: Recipe name, 4: Recipe variant name, 5: Simulation variant name, 6: Creation date of variant. |

SIMU_COMPARISON_ISTID |

ID type of the selection list (Select in administration/selection lists). |

SIMU_DEFINITION_HEADER |

Definition of the header of the simulation variants: M - manual; A - automatic; 1 - append simulation name; 2 - append creation date for automatically created variants; Ex: M1,A2. |

SIMU_NK_PRICES |

Decimal places for prices in the simulation area. |

SIMU_PRICEXKG |

X value set |